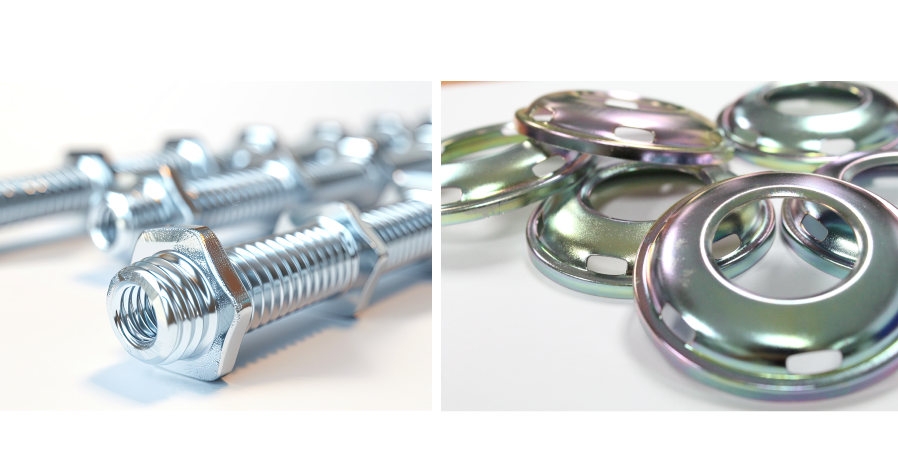

To enhance its corrosion resistance and appearance, passivation is typically applied, forming a protective film on the zinc surface. To meet global standards like WEEE, RoHS, and ELV, Auromex offers a comprehensive range of hexavalent-free trivalent chrome passivations, available in blue, iridescent, and black shades. Designed for acid and alkaline zinc plating, as well as zinc-nickel and zinc-iron processes, our products ensure excellent corrosion resistance with an attractive finish. Additionally, we provide cobalt-free to support green technology initiatives.

Tri-Chrome Blue Passivation for Zinc Barrel & Rack Applications

Tri-Chrome Blue Passivation for Zinc Barrel & Rack Applications

Tri-Chrome Blue Passivation for Zinc Barrel & Rack Applications

Tri-Chrome Blue Passivation for Zinc Barrel & Rack Applications

Tri-Chrome Blue Passivation for acid/alkaline Zinc

Anti corrosion additive for tri-chrome blue passivation

Tri-Chrome Blue Passivation for Zinc-Nickel Alloy

Tri-Chrome Blue Passivation for Zinc-Nickel Alloy

Tri-Chrome Blue Passivation, Cobalt-Free for Zinc-Nickel (12 – 15%) Alloys

Tri-Chrome Transparent Passivation for Zinc-Nickel (12 – 16%) Alloys

Tri-Chrome Iridescence Passivation for Zinc Barrel & Rack Applications

Thick tri-chrome iridescent passivation with high chemical reactivity and superior corrosion resistance

Thick Tri-Chrome Iridescence Passivation for Zinc Barrel & Rack Applications

High Corrosion-Resistant Iridescent Trivalent Chrome Passivation for Zinc Deposits

Tri-Chrome Iridescent Passivation for Zinc Barrel & Rack Applications

Tri-Chrome Black Passivation for Zinc Electrodeposits

High-performance deep black passivation for alkaline zinc deposits

Tri-Chrome Black Passivation for Alkaline Zinc Electrodeposits

Black Passivation for Acid Zinc Electrodeposits

Tri-Chrome Black Passivation for Zinc-Nickel Alloy Electrodeposits

Tri-chrome black passivation without cobalt, designed for alkaline ZnNi deposits

Tri-Chrome Black Passivation for Zinc-Nickel Alloy Electrodeposits